In India, Kirana stores remain the heart of the supply chain. Indeed they are vital to the nation's economy, as well as its customers. But with this role come certain challenges. For example, there are over 6 million Kirana businesses across India today – and only a small fraction of these stay in business for a decade or more! How can businesses keep their fleet consistent and maintain growth? What does keeping a fleet consistent look like? What does it take to build a viable logistics network for your Kirana store? Does everyone have the opportunity to take advantage of India's logistic potential?

The geographical scope, the low development level and the small size of India's population make it difficult for Kirana stores to provide adequate logistics support. These stores buy from producers, then process their individual orders and forward each item to the market destination by using their own transport fleet or hiring local truckers.

In a nutshell, supply chain management and adequate logistics can support are necessary for Kirana stores to survive in the market.

Role of Supply Chain Management in Kirana Store Recovery

Supply Chain Management is the backbone of any business, and that is especially true for Kirana stores. SCM helps to ensure that the right products are delivered to the store at the right time, and that inventory is properly managed. This is essential for stores that rely on a limited inventory selection, as Kirana stores do.

In addition to ensuring that products are delivered on time, SCM also helps to streamline the ordering process. This makes it easier for store owners to order the products they need, and helps to ensure that orders are placed in a timely manner. This is especially important for stores that experience stock-outs or out-of-stock situations.

How Does Supply Chain Management Help Kirana Stores Recover?

You might be wondering how exactly Supply Chain Management (SCM) can help kirana stores recover from a crisis. Let's take a closer look:

- The first way SCM can help is by reducing stock outages. By forecasting demand and ensuring that stores have the right amount of stock on hand, SCM can help to prevent shortages that can lead to empty shelves and lost sales.

- Second, SCM can help to speed up the distribution of goods. By coordinating the delivery of products from suppliers to stores, SCM can help to ensure that products reach stores as quickly as possible, minimizing the impact of a crisis.

- Finally, SCM can help to reduce costs and improve efficiency. By optimizing the supply chain network, SCM can help to minimize waste and reduce the need for stock storage. This can help to improve the profitability of stores during a crisis.

Read More: Top Fleet Management Trends for the Fast Moving Consumer Goods Industry

Benefits of Supply Chain Management for Kirana Stores

There are several benefits of using supply chain management for Kirana stores. Some of the key benefits are as follows:

Improved inventory management

One of the key benefits of using supply chain management is improved inventory management. This helps to ensure that the right items are available in the right quantities, at the right time. This can help to improve store operations and provide a better customer experience.

Reduced wastage

Supply chain management can help to reduce wastage by ensuring that products are delivered to stores in the correct quantities. This can help to save money and improve store profitability.

Faster response to changes in demand

Supply chain management can help to speed up the response to changes in demand, ensuring that products are delivered quickly and efficiently to meet customer needs. This can help kirana stores to stay competitive and improve customer loyalty.

Recommended Reading: Top 6 Benefits of Non-Asset Based 3PL Services Over Asset Based 3PL Services

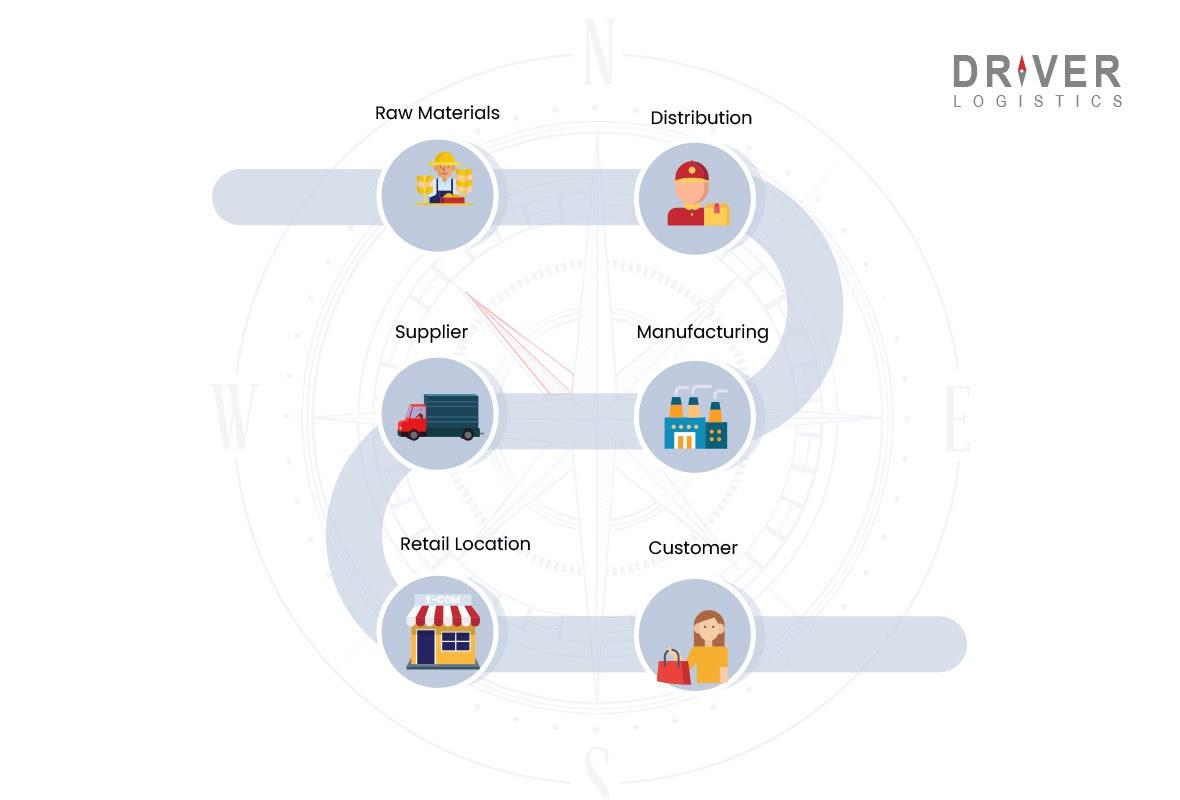

Types of Supply Chain Management

There are four types of supply chain management:

Demand management: Demand management involves forecasting customer demand and organizing production to meet that demand.

Production planning: Production planning creates a production schedule that takes into account the availability of resources, the type of product being produced, and the desired delivery time.

Inventory management: Inventory management determines how much inventory is needed to meet customer demand

Order fulfillment: Order fulfillment ensures that orders are filled quickly and accurately.

Each one plays an important role in ensuring that kirana stores have the necessary supplies to operate effectively.

What Are the Challenges of Supply Chain Management in Kirana Stores?

When it comes to supply chain management, kirana stores face a unique set of challenges.

One of the biggest challenges is dealing with stock outages and late deliveries. This can be caused by a number of factors, such as inaccurate forecasting, supplier failure, and natural disasters.

Another challenge is managing inventory. Because kirana stores carry a large variety of products, it can be difficult to track stock levels and ensure that the right products are available at the right time. Managing inventory also requires a lot of manpower, which can be difficult to manage when the store is already short-staffed.

Finally, kirana stores often have to deal with last-minute changes in demand, which can be difficult to accommodate due to the lack of planning and forecasting.

How to Overcome the Challenges of Supply Chain Management in Kirana Stores?

There are a few challenges that kirana stores face when it comes to supply chain management. The first is ensuring that they have enough stock to meet customer demand. This can be difficult, as stock needs to be ordered well in advance and sometimes it can be difficult to predict demand accurately.

Another challenge is ensuring that the products they order are of good quality and meet customer expectations. This can be difficult when dealing with smaller suppliers, as there is less flexibility when it comes to returns or exchanges.

Finally, kirana stores need to be efficient in their distribution process, ensuring that products reach the right store at the right time. This can be difficult when there are a large number of stores and each store has its own unique requirements.

Relevant Reading: Exploring the Possibilities in Supply Chain Transparency: Defining Structure & Steps for Improvement

Partner With A Logistics Service Provider to Improve Your Kirana Store

When a kirana store is hit by a natural disaster or faces a stock crisis, the role of supply chain management is crucial in helping them recover. Supply chain management ensures that the right goods and materials are delivered to the store at the right time, so they can continue to function and keep serving their customers.

In times of crisis, supply chain management becomes even more crucial in order to help the kirana store keep its head above water. Thanks to the timely intervention of supply chain management, many kirana stores have been able to recover and continue serving their community.