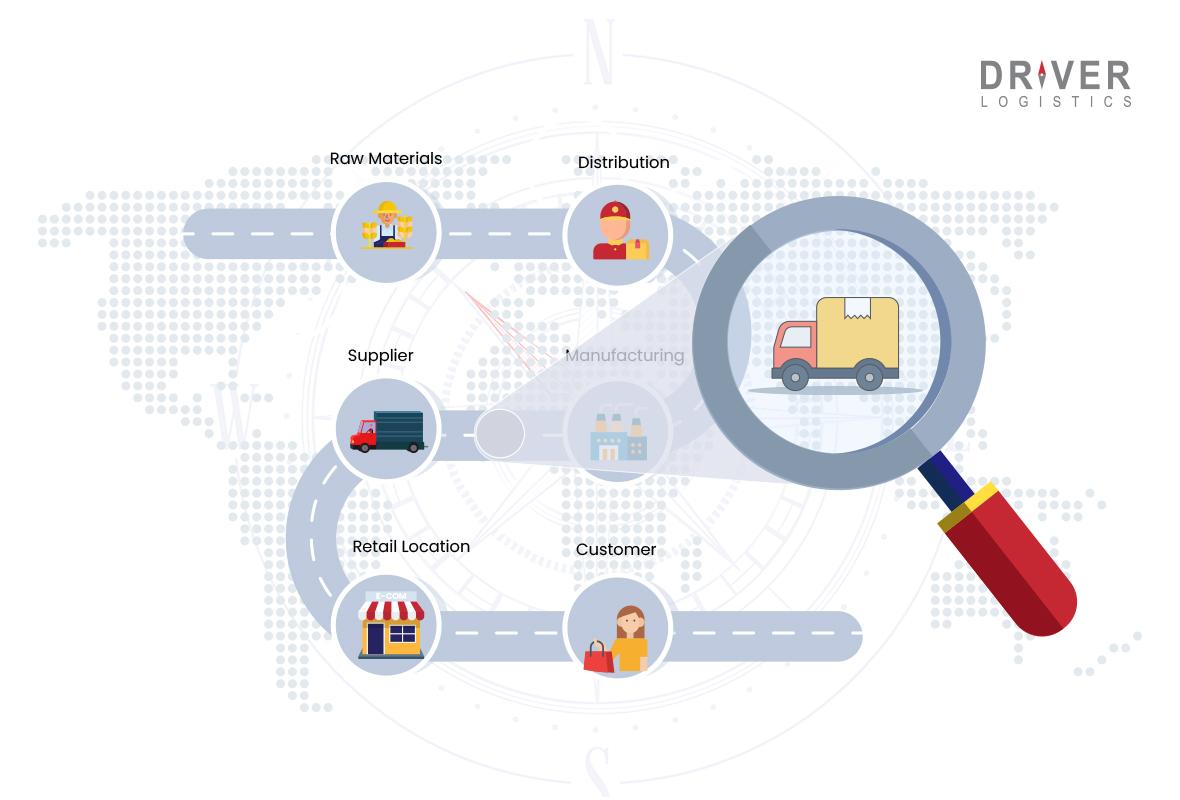

Businesses strive for an integrated logistics solution that can act as the backbone of their organization to compete in today's global and digital world. Integrated logistics is a critical method for maintaining flexible supply networks. Everything is linked – resources, items, information, operators, and departments — with a single goal in mind: to deliver orders to consumers as quickly as possible.

Supply chain and procurement, as well as customer fulfilment and returns, are all supported byintegrated logistics systems. This includes predicting consumer requirements and expectations, obtaining, storing, and shipping raw materials, and organising delivery.

What is Integrated Logistics & How Can it Serve Your Business Needs?

The term "integrated logistics" refers to a supply-chain organisation and business model in which departments, procedures, resources, and flows are all coordinated to function in the same direction.

Logistics is an interdepartmental procedure, including almost all divisions within a firm. When they operate together, processes become much more smooth, and orders can be dispatched much more swiftly.

Changes in demand and the arrival of rivals have compelled businesses to seek formulae that optimise their processes, shorten cycles, and reduce costs. Coordination across an organization's numerous divisions enables it to have flexible, agile operations that allow it to adapt quickly and correctly to new trends.

Read More: Top Reasons Why You Need Blockchain in Logistics to Boost Supply Chain Efficiency

Benefits of Integrated Logistics

The opportunities and benefits that integrated logistics provides to an organization are vast. Here are a few of them:

Enhanced coordination & Transparency

It is critical in an integrated supply chain to connect with as many applications as possible, to enable strong collaboration with the business systems. An integrated supply chain reduces costs, waste, manufacturing time, and response time. Moreover, it emphasises centralization to enable company-wide visibility rather than enabling distinctive organizational activities to operate independently.

Working in a siloed environment is no longer a viable option. It is critical to integrate applications in your logistics ecosystem and enable continuous data flow to achieve agility in business operations.

By aligning and integrating your supply chain, you can ensure various departments in your logistics or supply chain ecosystem have easy access to all the data. Cross-departmental visibility is an imperative factor for every logistics unit to make informed decisions.

Easy Access to Data & Meet Consumer Demand

Unlimited access to data is one of the benefits of digitalization. However, it's crucial to maintain, organise and distribute these data from a single interface to ensure security and speed up time to market.

With an integrated logistics system, these supply chain leaders have ample opportunity to utilise these data assets to get useful insights into consumer behaviour, gaps and blockages in demand, supply, and market trends.

In an integrated supply chain system, companies are better positioned to foresee demand and respond appropriately. Moreover, a robust ERP platform guarantees easy access to data, product innovation, and finance strategies.

Reduce Total Operational Cost

Every supply chain business strives to lower operating expenses while maintaining customer satisfaction and product quality.

Companies look for advanced operational efficiencies, which can result in cost reductions. Integrated logistics service is responsible for the entire supply chain system, and their infrastructure efficiencies in transportation, sourcing, warehouse availability, and so on help companies reduce investment and maintenance costs, as well as spot efficiencies to create extra savings.

Integrating an ERP system into your disjointed logistics infrastructure centralises your work, allowing you to save time and money wasted on human input. Most firms see an easier interchange of business information after implementing a solid ERP platform, which is aided by a simpler movement of knowledge, information, and data between departments.

More profitable margins

To achieve lower costs and a better bottom line, your manufacturing & logistics operations should be matched against demand. "Smart and integrated solutions provide complete visibility, control, and efficiency in critical areas such as vendor managed inventory, quotation information, payments, and so on, increasing profitability."

A well-integrated logistics system can provide room for higher profit margins by procuring higher-quality or more cost-effective commodities, or by discovering more efficient ways to store or transfer resources and goods. These operational efficiencies can contribute to higher profitability.

Eliminates Waste from Raw materials

It is difficult to maintain a sustainable supply chain.

Waste reduction is a significant concern for businesses, and an integrated logistics system enables precise forecast of client demands, scheduling raw material purchases, and assuring on-time product delivery. It is easier for firms to balance inventories and meet consumer expectations when they have an integrated logistics system in place.

Here are some examples of how ERP software may assist your firm in reducing or eliminating waste during production:

- In any production process, there are always faulty items. An integrated ERP software, on the other hand, may aid in the detection, monitoring, and tracking of errors by keeping all production data. ERP software may inform you of any faults or problems by monitoring the manufacturing lines.

- In a traditional legacy system, employees in a supply chain system must wait for authorization, supplies, information, and decisions, which may limit their capacity to act. It usually results in a loss of synchronism, administrative bottlenecks, and a slow pace of production. However, the problem might be rectified by using ERP software, which simplifies and streamlines the production process. By ensuring that all team members are on the same page, ERP increases automation and operational coordination.

- With a well-mapped ERP system, you will be able to automate the majority of the tasks involved in shipment and delivery. ERP software may also be used to improve the efficiency of your supply chain and track the performance of your logistics.

- A supply chain may produce surplus items that exceed the storage capacity of its warehouses as well as market demand. Inventory overloads, inadequate supply chain management, misuse of manufacturing lines, and a lack of precise forecasts are common causes of overproduction. It can be difficult to manage, especially when perishable goods are involved.

Recommended Reading: How express delivery can benefit your eCommerce business?

3 Tips to Implement Integrated Logistics Effectively

Ready to implement integrated logistics solutions effectively. Here are the 3 crucial steps you must know:

Analyse the Logistics of Your Current Supply Chain

It probably goes without saying that the first and arguably the most important step in implementing any new technology in your business is planning. The outcome of the planning step will define the rest of the project and will help you to monitor and measure the effectiveness of the chosen solution throughout its lifetime.

Choose the Right Hardware & Software

Every business has its own peculiarities which must be considered while implementing new technology. There are hundreds of integrated solutions in the market. For implementing the right one, it is necessary to analyse your supply chain and understand your pain points. Moreover, make sure the solution or technology you are implementing is compatible with other applications in your supply chain unit.

In order for data to be exchanged and delivered between applications, a technically unified software environment is required. Furthermore, while picking an ERP for your supply chain or logistics ecosystem, you must be completely aware of the expertise and capability of your team members.

Your employees must be aware of the resources available to them as well. Having a few team members in your firm who have previous experience with an ERP system and can manage technical components and challenges with that specific ERP will be an asset.

Educate Your Employees on the Adopted Integration Model

It is not just enough to have stellar technology integration. Before businesses can reap the benefits of their new software, they must first overcome the most difficult barrier to technology integration: staff training. Provide technical help, a range of reference formats, and a culture of communication and cooperation to workers throughout the training process.

The issue is that employees often resist learning new software. They're already used to working around problems in the current system, and they may feel irritated by the disruption that even beneficial adjustments cause. This might give the appearance that the previous system was superior. Making training as pleasant as possible encourages staff to support new software.

Relevant Reading: Reverse Logistics: A Guide to Key Strategies & Benefits

Find your Integrated Logistics Solution to Enhance Supply chain Workflow

It is not straightforward to implement an integrated end-to-end supply chain system. There are several elements to consider, as well as several solutions that may be appropriate for your organisation. Especially if you are partnering with a 3PL or 3rd party logistics provider to outsource logistical needs, linking your ERP with a 3PL system may greatly enhance logistical management and oversight over distant inventory.